Commercial Battery Zero-Turns. Is the investment worth it?

Commercial battery zero-turns and stand-ons. Are they worth it?

The battery revolution is well and truly amongst us. Battery cars are becoming more prominent and battery equipment is definitely making leaps and bounds. As gardeners, contractors or acreage owners we are already fully accustomed to the variety of handheld battery equipment on the market today. Most of us have used line trimmers, hedge cutters, self-propelled mowers, blowers and chainsaws powered by a lithium batteries and the benefits are clear – they are quieter, less maintenance, no fumes, no fuel and much more! Alongside this we have now begun to see the introduction of battery commercial zero-turn on the market. Many brands are introducing us to a new way of cutting grass at the expense of a much larger capital investment but the question remains, is it worth it? We will dive a little into the products now available (or coming) to Australia mostly focusing on the commercial units we have available at our dealership such as Greenworks and Toro. There is a substantial amount of factors that each individual party must consider before going green and hopefully, this allows you to understand some of those more clearly.

Benefits

Running costs and downtime:

It’s clear that the running costs of a battery commercial zero turn mower much cheaper than the cost of running a petrol-powered unit. There are no fuel costs, less maintenance and less moving parts, whilst another cost that can be considered is down-time costs recovered for common petrol-powered unit repairs.

The battery machines have as much as 300 less moving parts when compared to a petrol machine. There are no belts on the deck, no idler pulleys, minimal grease points, no engine to service and more. This consequently means you will have no belts coming off during mowing, no air filters to clean, no idler pulleys breaking down out in the field and no engine to watch whilst operating the unit. As a sole trader invested in their equipment, this might not mean a huge amount as you are most likely across your machine and maintain it yourself regularly. This means common mishaps may be easily fixed by yourself in the field or after work but for a commercial team that uses operators, or councils with employees the downtime spent when issues like these arise can be costly and frustrating for contracts that need to be completed as they commonly don't work on their own equipment.

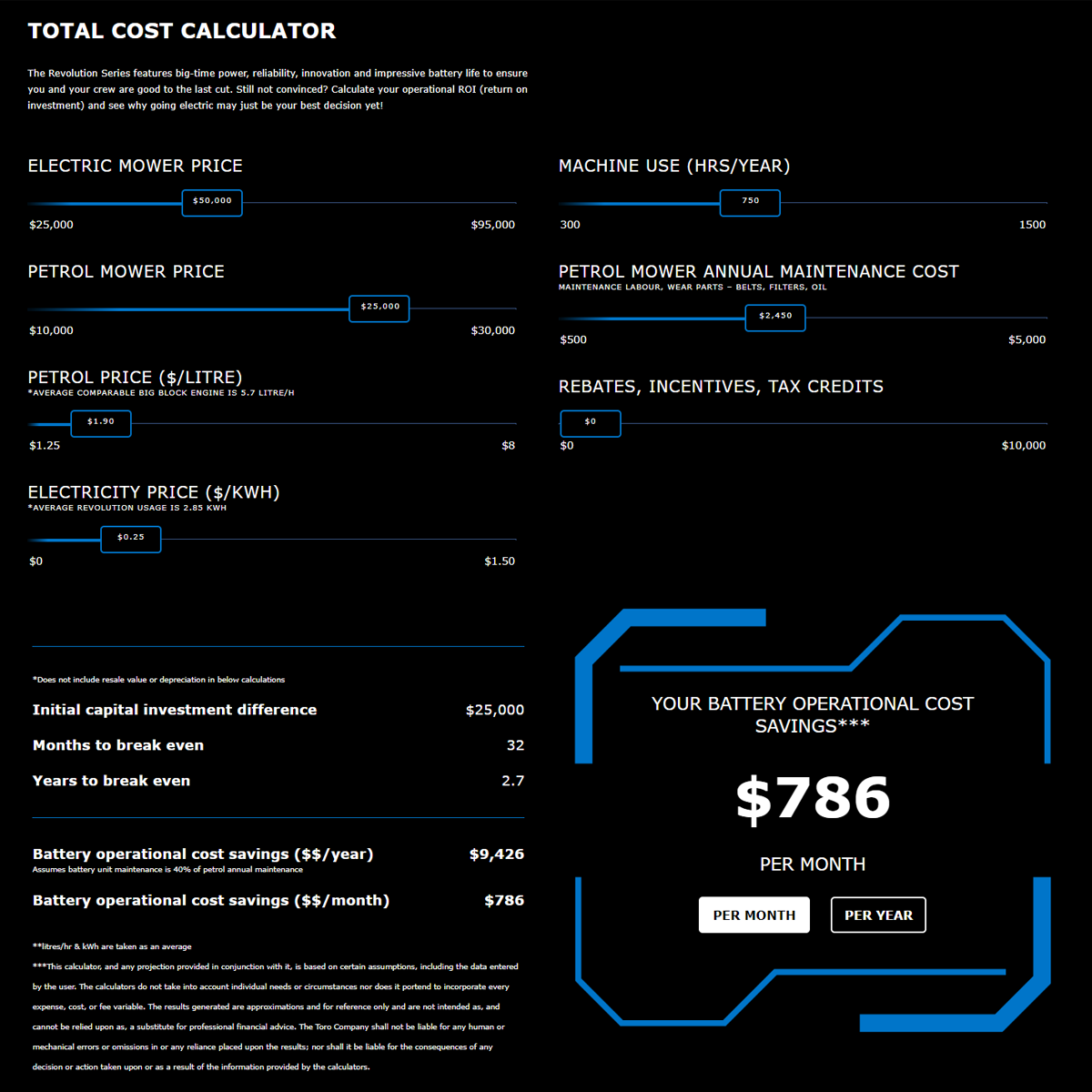

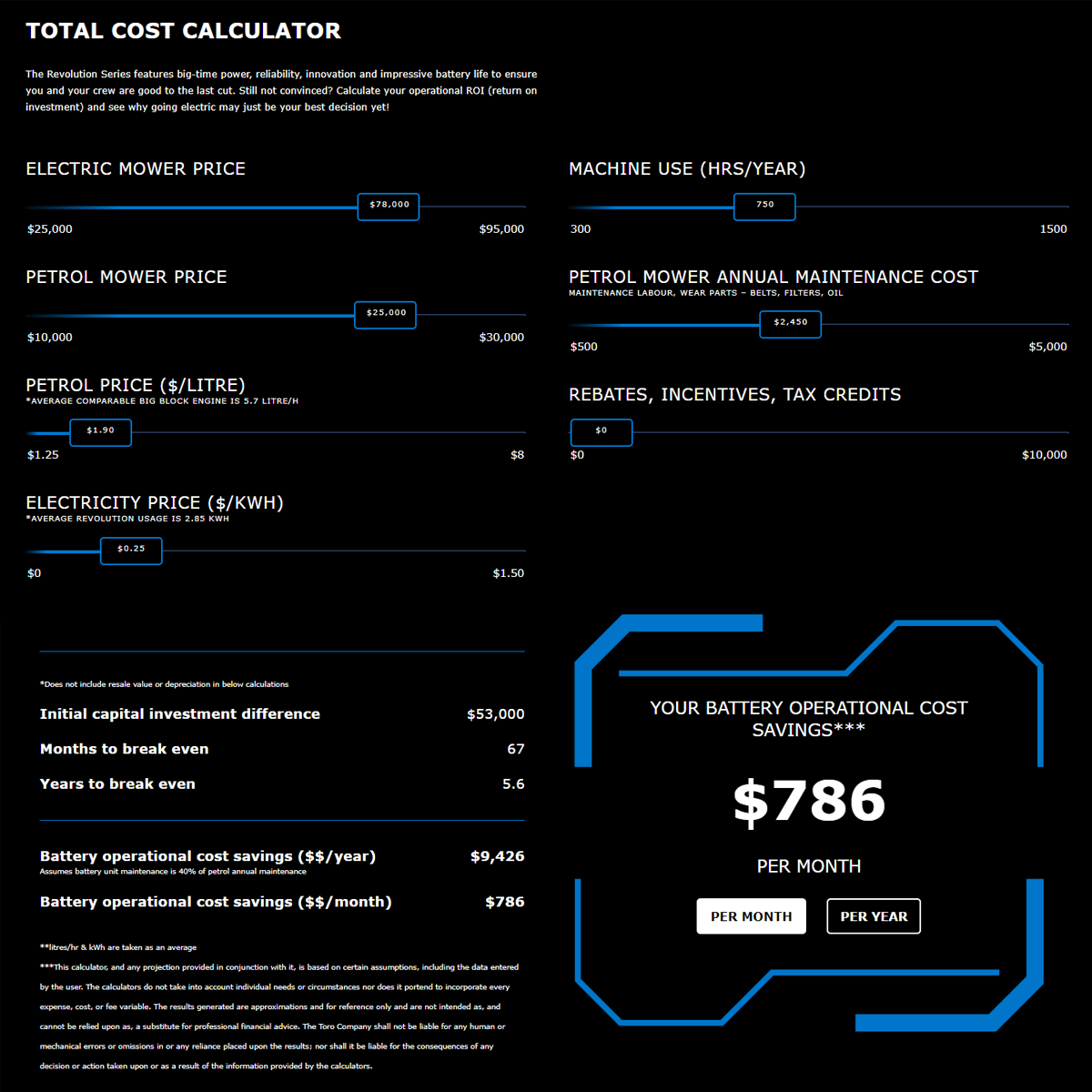

There is no hiding away from the costs of fuel and oil when it comes to running a petrol-powered machine. With the cost of fuel sitting around $1.90 per litre (06-04-2024) – you can quickly see the savings. We have used a cost calculator that takes into account the initial investment difference on a battery unit vs a petrol one and then the running costs of the petrol machine. Below, you can see, to reach a breakeven point in your investment the time that needs to lapse after you buy. After this breakeven point your maintenance cost benefit begins to be a profit-saving feature of your initial buy. We have done one for both a Greenworks machine ($50K) and a Toro revolution ($78k). Please see the breakdowns in the images below with the Greenworks machine being first and the Toro Revolution being second.

We have obviously made some general assumptions such as the unit does 750 hours a year of commercial mowing which is 2.88 hours per day on a 5 day working week. This will not suit every operator but it’s a starting point. We have also compared it to the purchase of a petrol commercial zero-turn valued at $25,000 and you would spend $2,450 in repairs on these petrol units each year. This figure could easily be more but keep in mind it doesn’t count parts that you would also put on the battery unit like blades. It only counts parts found on the petrol unit only such as belts, pulleys, oil, filters and maintenance spent on the engine/ fixing these parts.

The Greenworks machines purchase price is $50,000 and takes approx. 2.7 years (32 months) to break even against the petrol machine with a maintenance saving of $786 per/month assuming you are doing that many hours in a machine. This doesn’t take into account the other benefits the machine has when it comes to downtime for that maintenance and more. This is purely a cost-benefit of the unit and nothing else. In theory, after that 2.7 year breakeven mark you will be putting $786 in operational cost onto your bottom line – that’s a huge amount if you have multiple machines.

The Toro, being a much larger investment at $78,000 takes 5.6 years to break even when taking into account the operational costs. It’s a much larger time frame as your capital outlay compared to the petrol machine is twice as much. When it comes to the machines themselves you would have to dive into the technology and benefits of both machines to determine whether that cost difference is justified when it comes to your business plan.

Its important to note that we are not ignoring the fact that there is a possibility you could run into costs associated with your battery unit too such as blade motors damaged due to impacts but it is clear that there is a significant operational cost benefit in favour of the battery machines. Greenworks blade motors are roughly the same cost as a complete spindle assembly on a commercial Toro; $850. However, unlike a battery motor – a petrol spindle can be broken down and individual components can be replaced/ maintained.

Performance:

The cutting performance of battery zero-turns and stand-ons was surprisingly superior to that of petrol units. Those who use machines know that when grass gets thick and wet then belts can slip and engines can labour. You just don’t get that with a commercial battery machine. They utilise brushless motors on top of each individual blade that can handle significantly more load than a belt-driven petrol machine without being compromised.

This results in better cuts at higher ground speeds and greater performance in heavier, wet grass. We have used both the Toro Revolution and the Greenworks OptimusZ and both machines were an elite finishing mower and the cutting superiority over a petrol unit was definitely evident.

Noise:

We have to briefly discuss the noise benefits of going battery as they can allow a contractor or team to start much earlier than usual. These units are up to 3x quieter than a traditional petrol-driven machine. This allows you to start earlier and go later if desired without disturbing people you normally would. More time mowing means more productivity and more income.

Going green:

This third and final benefit we will briefly discuss is the benefit of going green and reducing your footprint. It's obvious that larger corporations and councils are feeling some pressure to reduce their environmental impact and battery commercial equipment is definitely one way to go about it. These machines are more environmentally friendly than petrol-driven machines and are a great way to showcase that you are making an effort to minimise your impact on the environment. If you are a contractor this could open up business opportunities as equipment that has less of an environmental impact when in operation is a definite competitive advantage when going for large contracts.

One interesting topic of conversation is also government incentives and rebates. There is currently nothing on offer in Australia in the form of rebates for going green when it comes to commercial battery zero-turns. We have seen overseas that government incentives and rebates can change the landscape as it brings the breakeven point even closer to the date of purchase making them a much more enticing purchase. If Australia adopts a similar approach then we may see a much larger swing towards commercial battery equipment.

Disadvantages:

Battery life and charging?:

The life and runtime of the batteries are definitely a hot topic when discussing whether or not to go battery-powered. When it comes to commercial machines I think it is fair to say that the top-end units are equipped to mow grass for a full day on a single charge. The Greenworks and Toro Revolution comfortably run for a day's worth of mowing. Toro claims up to 9 hours with the Greenworks 24kW battery claiming 7-8 hours of cutting although this might not suit everyone. There are a number of factors that play on the battery life such as cutting modes, thickness of the grass and mulching kits just to name a few.

One issue that we have seen arise is whether larger corporations or fleet managers that take equipment home with them run into the issue of whose power is being used to charge the company mower? It opens a can of worms for companies as employees are plugging these units into their own power and need to be compensated for that if it isn’t charged at the depot. There is ways around it like split meters etc but its all an added cost for the benefit of going battery.

One issue that we have seen arise is whether larger corporations or fleet managers that take equipment home with them run into the issue of whose power is being used to charge the company mower? It opens a can of worms for companies as employees are plugging these units into their own power and need to be compensated for that if it isn’t charged at the depot. There is ways around it like split meters etc but its all an added cost for the benefit of going battery.

The actual life of the battery. Greenworks claims to have a 2000 charge cycle before deterioration in the battery is seen and Toro state the battery will most definitely last the life of the mower. Taking Greenworks 2000 charge cycles and a run time of 7-8 hours means these machines will get charged at 4-5 times a week which is 260 times a year which is roughly 7.5 years before you see a reduction in the battery capacity. This is extremely good considering most councils and contractors turn their units over more frequently than that.

The cost of a replacement battery is obviously a huge scare factor and at the point of writing this post I am unsure how much a complete Greenworks battery is but its in the area of $17K - $19K which is obviously a significant cost and has to be a disadvantage. These costs will most likely see units moved on once outside warranty periods in my eyes.

In stating this the actual runtime for these units seem to now be meeting the mark. Councils, shires and the like can get a full day of cutting out of their Greenworks and Toro units which is the standard that had to be met.

New technology:

New tech can obviously be a benefit for obvious reasons but I am including it as a disadvantage also due to the workshop nature found in the small engine industry and the drastic change this equipment brings to it. Small engine mechanics and techs are not immune to electrical features on a unit as they have been working with EFI technology and ECU systems in recent years. Although these units are completely electrical and that will definitely create some boundaries going forward as techs need to reskill (or dealers needs to hire an auto electrician!). Working with incredible brands definitely helps as there is significant support and training available to dealers but it still takes time and there is plenty of unknowns. This may result in longer downtimes in the feature as electrical issues and faults can most definitely be harder to find and diagnose – this is clear.

With both the Greenworks and Toro battery units now here, a select number of our techs and staff have already undertaken training relating the sales, servicing and upkeep of there battery units. This ensures the service backup is sustained to the same quality that we provide for our petrol and diesel machines.

Initial capital outlay cost:

The initial outlay, even though eventually offset by operation costs has to be a hurdle for some purchasers. Depending on budget and financing options – to put so much capital into one machine can hinder the growth of other areas of a contractors business. If there is enough work they can purchase 2x Toro petrol units in the place of 1x Greenworks machine (3x petrol units in the place of a Toro!). Although for larger corporations, governments and shires the capital outlay may not hinder other operations so the purchase may make sense.

However, breaking down the payment via a financing option may reduce the hindrance of a capital outlay. Rough numbers on a 60-month loan for a $50,000 battery mower is $265 per week and on a petrol mower at $25,000 you are looking at $135 – that’s a difference of $130. Depending on each individual's circumstances you might find yourself spending that amount in fuel each week!

Conclusion:

I think it's clear that battery zero-turns in a commercial application have a place in Australia and the industry. Although, the initial capital investment is high it is clear these are quickly offset over the first years of the life of the machine. In addition, for those of you who are eager to dabble into a more expensive machine, you may see your business thrive with new opportunities and increased profit margins after operation cost benefits and capital investment break even. When it comes to larger businesses, schools, councils, shires and the like, these are the target markets for these units. Reducing operating costs, reducing noise, and reducing their environmental impact are all key advantages these potential customers will benefit from and the capital outlay not being as much of a hurdle.

There are loads of other considerations that this article does not consider – if you want more personal advice as to whether a battery unit is suitable for your application please feel free to reach out to a sales member in our team. We can guide you through the units we have available, their perks, quotes and also arrange demonstrations.

Picking a machine:

Each larger manufacturer is developing and releasing battery commercial zero-turns and stand-ons with many existing players already in the game. As a dealership the market for these machines within Australia isn’t that large meaning that not all brands can dominate the space – there just isn’t enough people here. We will take a very brief look at the two brands we have available at Hendersons and touch on what we like about each unit in comparison.

Ride and steering:

Both machines are comfortable. Each machine has an adjustable seat to suit your weight and features armrests as standard. In comparison, the Toro seat is marginally more comfortable if we are splitting hairs.

The Toro unit steered smoother and replicated a petrol zero-turn drive making it easier to transition to. The Greenworks unit drove well, and the top speed was much faster than the Toro but the lap bars were more sensitive which took a while to adjust too. There is a drive update that is fixing the sensitivity of the steering. With the stand-on units the springs on the Greenworks control levers take a while to adjust too as they spring out easily, the Toro unit utilises a slightly different setup with one control lever (the left) always engaged into the drive position with the right lever the only one you need to pull in to engage the drive. This small feature made the machine much easier to operate as you continuously had a stabilising handle within your grasp, so you rarely loose balance. Please refer to the image below.

Operator Panel:

Greenworks wins this hands down. The touchscreen electronic dash on the Greenworks machine is vibrant, easy to read and gives you several cutting modes, specifications and unit options. This greatly increases the user experience and gives you greater control over your unit. There are some neat features such as flashing lights, cutting specs and more. The Toro dash is simple – don’t get me wrong it does the job and at the end of the day it isn't purchased for the electronic screen. I liken the Toro to the Toyota Landcruiser. Bulletproof, popular, expensive but the interior is like an old Manga. But it works and probably won't break. Check out both and let me know what you think! The Greenworks one is definitely elite in its design and has some awesome features. The built-in light control is super handy, the traction control will be ideal in the wet too! It also has inbuilt 4G connection for software updates on the go.

Battery:

The runtime of both the batteries is extremely similar and the overall life on paper seems the same but due to their limited life in the market, there is not much concrete evidence to determine which is longer lasting. In our limited experience with the units so far I think it's important to note the Toro battery technology. Toro utilises several battery packs with independent battery management systems. This advantage allows the system to recognise if one battery pack is causing issues/ deteriorating and allows that battery pack to be changed itself rather than the complete battery. This from a servicing point of view down the track may bit a pivotal cost saving although we are yet to compare a battery pack cost from Toro against the complete battery from Greenworks - it could be similar anyway! See the quick view below to see how the Revolution battery pack works.

Decks:

The Toro Revolution features the well-known Turbo-Force Toro deck shell which is 7 gauge thick with a welded front bumper bar. This deck is proven in the commercial landscape being used on the commercial 4000, 5000 and 6000 series already. The Greenworks deck is also 7 gauge thick with a welded front bumper although these decks are less proven as they are a new range being produced by Greenworks. The Toro deck features the well-known baffle adjustment lever to control your clippings when needed and the Greenworks does not. The Brushless motors on the deck are almost flush with the housing on the Greenworks unit making it much easier to clean and less likely to collect debris whereas the Toro motors stick up from the deck much higher.

The Toro machines are available in 48”, 52” and 60” cutting decks with mulching kits available for all decks. The Greenworks machines are also available in those three decks, but they are also introducing a 60” rear discharge deck which has seen a great amount of interest of late. Rear discharge decks are favoured by a lot of the key target market customers due to how much safer they are when operating. The Greenworks side discharge models can also be fitted with mulch kits but it is important to note that mulch kits place more stress on blade motors and therefore do reduce product runtime by roughly 10%.

**Update** 2024 July - Toro revolution rear discharge decks have been added to their options. There is either a 48 or 52 inch rear discharge deck option now available,

Tech support:

Toro is arguably the best grounds-cutting manufacturing company in the world. They dominant contractor divisions and golf courses alike. With this dominance, we see their technical division and training regimes being way ahead of other brands. The technical teams allocating a significant amount of time to their dealer network already with training modules and training days already being held to upskill their dealers. Greenworks has also been holding tech support meetings to train and advise their new dealer network in Australia, selected sales and technical staff have attended Greenworks headquarters in Melbourne to test, diagnose and work with a number of these units under the guidance of Greenworks in order to upskill the dealers to support their battery products once in the field.

Conclusion:

As for which machine is better than the other it is too early to tell. It's obvious that Toro is a much more expensive unit and whether they are worth the extra 50% on top of a brand like Greenworks only time will tell. Greenworks sure does have a sleek design and a wider variety of options in deck sizes, types and battery options with the performance levels thus far impressing our dealership. It is clear Toro has a stronger commercial presence amongst the target market, which may see them distribute a lot of units into this space on the back of an already impressive reputation due to cost being a significant barrier for a lot of customers already those that have the funds may opt for the Toro unit if they already have some petrol or diesel units in their fleet.

To us, both products drive well, cut well and overall perform exceptionally in Australian conditions. If you are in the market for a commercial battery zero turn then eithier brand will most likely satisfy your needs.

This area is a new space and over time we may still see significant variations in units on offer and technology available. Several other brands are entering the space such as Scag, Ego, John Deere which will make the area an interesting space too watch. We believe the market is very small with limited sales due to the barrier of cost to entry so whether or not all the brands stick around I'm not sure. Although it is clear the benefits are well and truly there if you are willing to transition across to a battery machine.

If you would like to demo either impressive machine or discuss more about your business, council, school or shire moving towards commercial battery mowers – please contact us today.

I will leave you below with a recent review video done on the Greenworks OptimusZ. Feel free to join the conversation and comment below.

Post a Comment

No comments yet. Start a discussion!