The world's first concrete demolition saw with a brake system! This demolition saw has a specific purpose on the construction site and is a great addition to your fleet of equipment making certain jobs much safer for the operators. This saw is specifically designed for limited access cuts such as situations like bottom portions of walls, cutting corners, and cutting the underside of in-ground pipes.

The guard can be rotated to open it up for certain cuts making it more suitable for tight spaces. The open guard makes this tool more dangerous to use though which is nullified by the use of the break which automatically applies itself when it senses the unit kickback during the cut instantly stopping the blades. This motion sensor break is the first of its kind on cutoff saws stopping a blade in a fraction of a second after kickback. Watch the video for more information and read the specifications and features below!

This tool has a specific purpose on the site and it's important for you to realise it's not designed to replace a TS 420/500/700/800 at all. This saw rotates the blades at 50% less speed than those other units but has more torque so that it does not bog down during these difficult cuts. The unit has fewer blades applicable to it and is more costly to maintain as the brake needs to be serviced, so it's important you're buying it for the right application as stated above. It's not for cutting paths etc. that's what your other Stihl Cutquik saws are for!

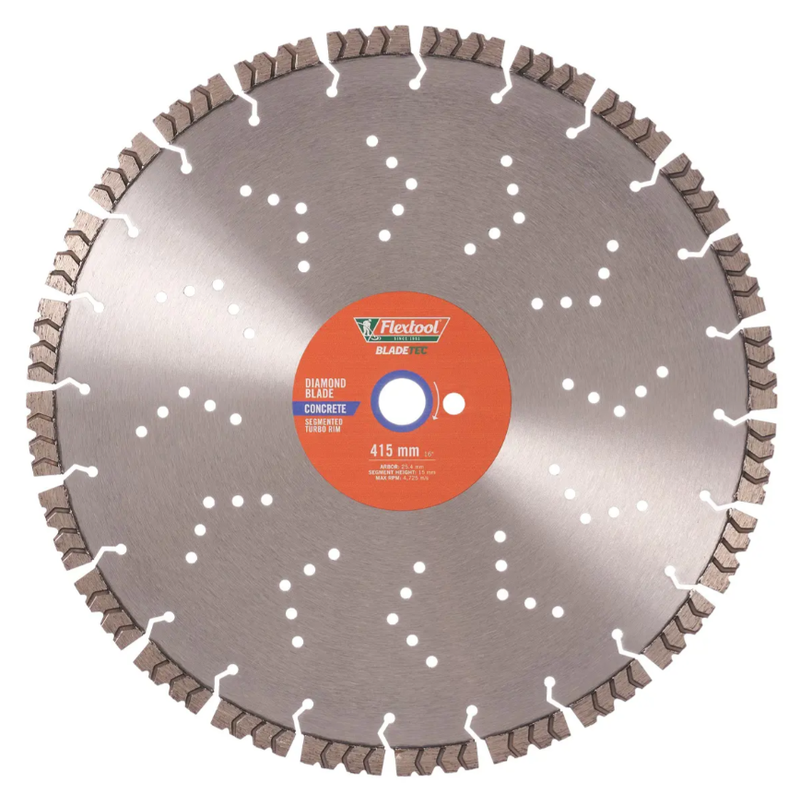

*For illustration purposes, the saw is shown with a diamond blade. It is not included in the price

Specifications

| Displacement | 66.7cc |

|---|---|

| Engine Power | 3.2 kW |

| Weight | 11.2kg (dry weight inc. guard and water attachment) |

| Maximum Spindle Speed | 2,525 rpm |

| Engine Speed | 9,000 rpm |

| Arbor Size | 20mm |

| Max. Wheel Size | 350mm (14") |

| Max. Cutting Depth | 125mm (4.9") |

| Power Source | Fuel (2-stroke) |

| Warranty | 2 year domestic warranty / 1 year commercial |

Features

| Stihl QuickStop Wheel Brake This allows the saw to be safely operated in the open guard position where the motion sensors will sense any kickback from the saw and instantly apply the break stopping the blade almost instantly. This makes it very safe to operate with the exposed blade showing and allows you to make cuts you wouldn't make with any other demo saw on the market. |

|---|---|

| Stihl X2 Air Filtration System The biggest operator fault that kills demolition saws (besides putting straight fuel in them....) is lack of air filter maintenance. These units get used and abused. The conditions they operate in mean that they are almost always operating in a dusty atmosphere sucking in air that is far from clean. That is why the air filter must be checked regularly but unfortunately it does not often occur. This saw features the Stihl X2 filter which is revolutionising demo saw maintenance by allowing them to last up to a year based on average cutting conditions. The system results in air entering the saw in a swirl motion which removes 80% of the dust before it reaches the filter. This pre cleaned air is then sifted through both the primary and secondary air filters before being sent into the engine. This results in it maintaining an incredible 99.96% cleaning efficiency!!!! |

| Electronic Water Control (EWC) This allows the operator to adjust the water disbursement whilst cutting and also turns the water off automatically when you release the trigger and leave it at idle! The system evenly disburses the water either side of the blade! |

| IntelliCarb Compensating Carburettor This is a Stihl innovation! The compensating carby is designed to automatically adjust the fuel/air ratio when the air filter becomes restricted or partially clogged to maintain the correct RPM and performance during operation. It uses the clean side of the air filter to control the diaphragm and flow of the fuel. As the filter becomes dirty and the air intake is restricted the IntelliCarb system adjusts the fuel flow to compensate for the decrease in the air flow. This is in contrast to competing models that have carburettors that utilise this air from the dirty side of the air box. |

| Anti-Vibraton System Using a demo saw always results is significant vibration causing fatigue for the operator. Thats why Stihl's anti-vibration system is an innovative piece of technology that sets it apart from the rest. The vibration system sees the oscillations from the engine dampened reducing the handle vibration. |

| Stihl ElastoStart Stihl elastostart reduces the shock caused by the compression of the engine when starting it. The shock is reduced by the users joints and muscles through the spring or rubber element in the starter handle making it more comfortable to start for the operator. |

| Adjustable Guard This is where the saw really sets itself apart. the rotating guard removes it out of the way to complete those near impossible cuts! |

| Two-stage Drive Belt ENGINE POWER FOR DEMANDING CUTS. The two-stage belt drive gives your cut-off machine extra torque at the cut-off wheel. This means that even challenging cuts can be made cleanly, as high engine power means the cut-off machine is unimpaired by high cutting pressure. |

Related Products

...

Oregon Power Match Sprocket Nose Guide Bar 16" #72 D176 3/8" Pitch .050" Ga

...

...

Oregon Bar 18" Versacut 3/8" Series 18" #75 D025 3/8" .063" 66dl

...